Add to Cart

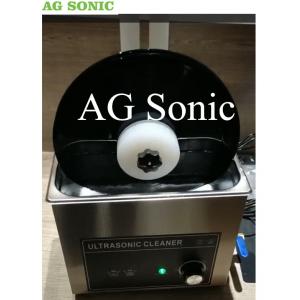

Ultrasonic Cleaner 6,5l 40khz Vinly Record Ultrasonic Cleaner With Drainage Valve Ultrasonic Vinyl Records Cleaner

Digital Series High Performance Ultrasonic Cleaning system offers a new dimension to your cleaning needs. The single chamber device is used to clean surgical instruments and other hardware with sonic energy in a water detergent solution.

All units are fabricated from solid stainless steel incorporating sweep frequency circuitry for a more uniform cleaning action.

Application of AG SONIC ultrasonic cleaner:

Jewelry Markets Retail/Wholesale: Tabletop models for cleaning finished goods, watches, chain, rings, etc. by the piece or in bulk.

Jewelry Manufacturing: General Jewelry Cleaning. Finite removal of investment after casting. Removal of rouge and other buffing and polishing compounds. Removal of oil/grease in chain manufacturing process.

Dental Labs: Can be used in the lab or office for finite cleaning of instruments with maximum power and delicate cleaning of cosmetic/corrective mouthpieces with adjustable power setting.

Hospital/Surgical: Absolute cleaning of surgical instruments, artificial components, etc... Sterilization chemicals can be added to beakers and used in the tank.

Tattoo: Clean needles, nozzles, brushes, filters.

Application:

1. For household: jewelry, ornaments, headwear, brooch, eyeglasses, watch chain, dvd, cd, razor, toothbrush, denture, tea sets and baby nipples, vegetables and fruits;

2. For eyeglasses and optical instruments: all optical instruments, such as parts of eyeglasses, magnifying glasses, telescope, microscope, camera…

3. For jade, accessories processing industry;

4. For watch industry, precise instruments;

5. For bank, office, arts and crafts, adverting industry and official supplies: such as printer, shower nozzle, technical pen, pen, painting brush, nozzle, sprayer, seal…

6. For communication equipment and electrical equipment maintenance: such as precise circuit board, spare parts of mobile phone, interphone, personal stereo…

7. For medical industry, schools: such as all kinds of medical instruments, denture, dental cast, lens, beaker and test tube of lab, mixture of all kinds of drug and reagent…

8. Gift for others.

Application:

Healthcare Dental and surgical instruments, optical, podiatry, general practice, hospitals, medical components

Manufacturing: Aerospace, pharmaceutical, defence, medical devices and orthopaedic implants, automotive, marine, filtration, moulding, food and beverage, plating & surface finishing, semi-conductors, printing technology and equipment.

Maintenance Automotive servicing, jewellery & watches, tools, weapons, Heat exchangers, oil & gas, commercial coffee boiler

Laboratory Scientific Research, Mixing, Cell Disruption, extraction, pharmaceutical Sonochemistry

Others window blind, golf club, tattoo equipment, anilox roller, music equipment, weapons, electronics, etc.

Features:

1. Ultrasonic power: 0-100% adjustable

2. Time setting: 0-30min or 24 hours continuous working

3. Heating: 20-80℃ adjustable

4: Ultrasonic frequency: 28 kHz or 40 kHz

5: Material: 2mm thickness SUS304 tank for acid-proof.

6: Improved PCB design for stable and durable industrial use

7: More strong and uniform ultrasonic wave

8: With free lid and stainless steel SUS304 basket

Features:

1. Stainless steel tank has resistance to wear and long work life.

2. With BLT type industrial ultrasonic transducer

3. with Stainless steel basket

4. Use just tab water, or industrial alcohol and solvent cleaner for higher cleaning requirement

5. Industrial control chip microcontroller. Flexible circuit boards control, more secure & stable

Vinly Record Ultrasonic Cleaner

| Model | TB-150A |

| Ultrasonic Frequency | 40,000 Hz |

| Material | SUS304 |

| Tank Capacity | 4.5L |

| Ultrasonic Power | 150 W |

| Heating power | 300W strong power, quick heating |

| Timer | 1-30min adjustable |

| Heater | 0-80C adjustable |

| Unit Size | 325 x 180 x 225 mm ( L x W x H ) |

| Tank Size | 300 x 150 x 100 mm ( L x W x H ) |

| Package Size | 410 x 255 x 310 mm ( L x W x H ) |

| N.W. | 4.5 kg |

| G.W. | 5.6 kg |

| Power Supply | AC 100 ~ 120V, 50 / 60Hz AC 220 ~ 240V, 50 / 60 Hz |

Features:

1. With BLT type industrial ultrasonic transducer

2. SUS304 tank with long work life

3. With SUS basket and Lid

4. Certificate: CE

5. With industrial pcb board control.

6. With 12months warranty

Motorcycle Carburetor Cleaner Packing

If any technical problem during warranty time, replacement parts will be sent free of charge.

Technical support is also available in whole time.

2. Our Advantage

1. Reply your enquiry in 24 working hours.

2. Experienced staffs answer all your questions in fluent English.

3. OEM is available if the quantity is large.

4. We offer very competitive for all our products.

3. After-sales

Our machines undergo an extensive and strict testing and quality control procedure, ensuring every item purchased meet global quality standards. It's safe and reliable quality for ultrasonic cleaning equipment.

1. AG SONIC technology limited, which engaged in ultrasonic cleaner field for more than 10 years. And the main products are ultrasonic cleaner with different capacity.

2. AG SONIC is an original ultrasonic manufacturer with R&D, production and sales teams. Our engineer is engaged in the filed for more than 20 years, so we have improved PCB design for stable and durable industrial use. High quality product and good after-sales services are available from us.

3. Not only standard ultrasonic cleaner, any non-standard can be designed by engineer.

Suggestion and drawing are professional for you.

4. Welcome to visit our factory in Shenzhen, and we are appreciate for your suggestions and hope to conduct business cooperation.

What is jewelry Ultrasonic Cleaning

In a process termed "cavitation", micron-size bubbles form and grow due to alternating positive and negative pressure waves in a solution. The bubbles subjected to these alternating pressure waves continue to grow until they reach resonant size. Just prior to the bubble implosion, there is a tremendous amount of energy stored inside the bubble itself. Temperature inside a cavitating bubble can be extremely high, with pressures up to 500 atm. The implosion event, when it occurs near a hard surface, changes the bubble into a suction jet about one-tenth the bubble size, which travels at speeds up to 400 km/hr away from the hard surface. With the combination of pressure, temperature, and velocity, the jet frees contaminants from their bonds with the substrate. Because of the inherently small size of the jet and the relatively large energy, ultrasonic cleaning has the ability to reach into small crevices and remove entrapped soils very effectively.

Benefits of cleaning jewelry with an ultrasonic cleaner

Steps to cleaning jewelry with an ultrasonic cleaner